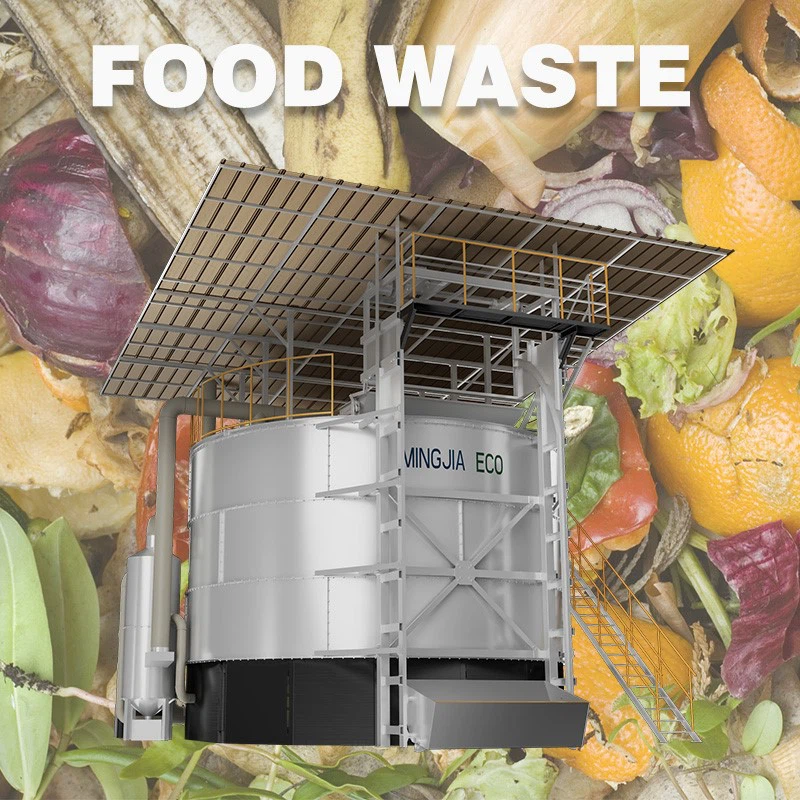

In modern urban life, the generation of municipal waste is a significant challenge. Municipal waste, which encompasses a wide range of materials from food scraps and yard waste to paper and cardboard, poses environmental threats if not managed properly. Mingjia's municipal waste compost machine emerges as a vital solution in the pursuit of sustainable waste management. This innovative equipment is designed to transform the bulk of organic - rich municipal waste into nutrient - rich compost, closing the loop on urban waste and providing a valuable resource for agriculture and horticulture.

Models

| Model | 11FFG-55 | 11FFG-80 | 11FFG-100 | 11FFG-120 | 11FFG-140 | 11FFG-160 | 11FFG-220 | 11FFG-280 |

| Body Volume | 55m³ | 80m³ | 100m³ | 120m³ | 140m³ | 160m³ | 220m³ | 280m³ |

| Power | 29.25kW | 34.25kW | 39.25kW | 39.25kW | 43.75kW | 43.75kW | 84.25kW | 109.6kW |

| Body Material | Double-layer Stainless Steel | |||||||

| handling capacity | 4-6m³ | 4-6m³ | 6-8m³ | 8-10m³ | 10-12m³ | 12-14m³ | 16-19m³ | 20-24m³ |

| Tip:The Moisture Content of Fresh Chicken Manure is 65-70% | ||||||||

Working Principle

Main Tank Body

Cylindrical Design

The core of the manure fermentation tank is its cylindrical - shaped main body, constructed from high - grade stainless steel. The cylindrical form offers several advantages. Firstly, it maximizes the volume - to - surface - area ratio, which is crucial for efficient heat transfer and mass exchange during fermentation. This design also helps to evenly distribute the internal pressure generated by the fermentation process, enhancing the tank's structural stability. The corrosion - resistant property of stainless steel is of utmost importance as waste can be highly corrosive , ensuring the long - term durability of the tank.

Double - walled Structure

Our fermentation tanks feature a double - walled structure. The space between the two walls is filled with insulation materials of polyurethane foam. This insulation layer helps to maintain a stable internal temperature, which is essential for the optimal growth of the aerobic bacteria involved in the fermentation process. It also reduces heat loss to the surrounding environment, making the fermentation process more energy - efficient.

Applications

Certification

Cooperation cases

Features

Exhibition

Shipment

Hot Tags: fermentation machine, China fermentation machine manufacturers, suppliers, 3bbl unitank, Aerobic Compost Tank, fermentation tank, jacketed fermentation tanks, Poultry Farm Composter, stainless steel fermentation tanks for sale